What Makes Planes Safe to Fly? The Critical Role of the Minimum Equipment List

Aviation is one of the safest modes of transportation, and this is largely due to stringent safety regulations and meticulous standards followed by airlines and aviation authorities. One of the critical components that ensures the airworthiness of an aircraft is the Minimum Equipment List (MEL). The MEL is an essential safety document that determines what equipment must be fully operational for an aircraft to legally and safely fly.

What is the Minimum Equipment List?

The Minimum Equipment List is a list of items and systems onboard an aircraft that are permitted to be inoperative under specific conditions while still allowing the plane to fly safely. This list is specific to each aircraft type and airline and is derived from the broader Master Minimum Equipment List (MMEL) issued by aviation regulatory authorities, such as the FAA (Federal Aviation Administration) or EASA (European Union Aviation Safety Agency).

While all equipment on an airplane is crucial to some extent, not every component is necessary for safe flight under all conditions. The MEL helps differentiate between equipment that is absolutely required for a particular flight and equipment that, while useful, can be deferred for repair or maintenance without compromising safety.

How the Minimum Equipment List Keeps Airplanes Safe

The MEL is integral to maintaining safety because it provides clear guidelines on when it is acceptable for an aircraft to fly with specific inoperative equipment, and under what conditions repairs can be postponed. Here’s how it contributes to safety:

- Operational Flexibility Without Compromising Safety: Air travel is a complex operation that requires strict scheduling. Grounding an aircraft for minor equipment issues can lead to significant delays, affecting thousands of passengers. The MEL allows pilots and maintenance teams to assess whether certain equipment can remain inoperative for a short period of time without increasing the risk to flight operations. For instance, if a passenger reading light is malfunctioning, this would not prevent the aircraft from operating safely.

- Clear Procedures for Deferred Maintenance: Each item on the MEL is assigned a specific timeframe, or "repair interval," within which it must be fixed. Depending on the severity and function of the equipment, repair intervals might range from a few days to a few weeks. This ensures that minor, non-critical issues can be repaired during routine maintenance schedules, while more serious problems are addressed before further flights.

- Ensuring Critical Systems Are Always Functional: The MEL distinguishes between non-essential items and critical equipment. For example, items such as navigation systems, engines, and flight controls are always required to be operational. In cases where essential systems fail, the MEL will prevent the aircraft from flying until the issues are resolved.

Example: Minimum Equipment List in Action

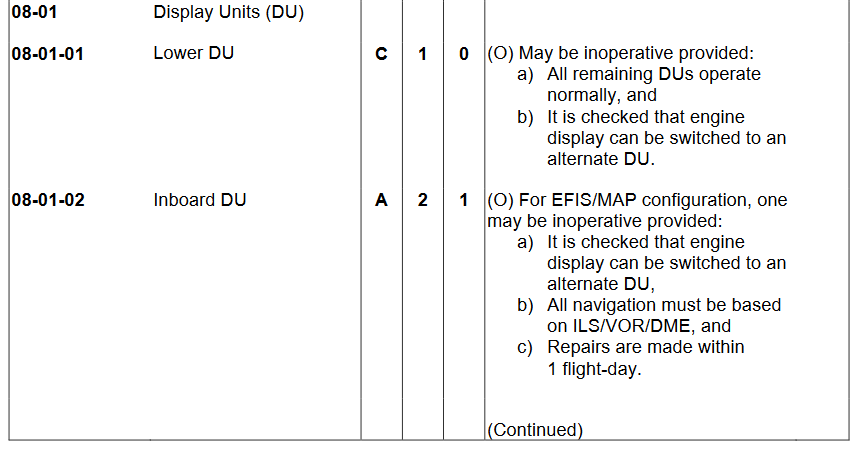

Let’s consider a typical scenario. Imagine a commercial airliner preparing for takeoff, but during the pre-flight checks, the pilot discovers that one of the aircraft’s cockpit display screens is malfunctioning. While the plane is equipped with multiple redundant systems, the MEL would specify whether it is safe to fly with the screen inoperative.

According to the MEL, the aircraft might be allowed to continue its flight if the malfunctioning display is a non-primary screen, as long as the other essential displays, such as the primary flight display and navigation systems, are fully functional. The MEL would provide clear instructions on how long the plane can continue flying before the faulty screen must be repaired, ensuring that the issue is addressed within a safe timeframe.

In this case, the MEL allows for flexibility in operations while still ensuring passenger safety by mandating that critical systems remain functional. The airline can avoid immediate cancellations, but the problem will still need to be fixed within the prescribed period.

Final Thoughts

The Minimum Equipment List (MEL) plays a vital role in keeping aircraft safe while allowing airlines to maintain efficient operations. By providing a structured approach to managing minor equipment failures, the MEL helps ensure that flights are not unnecessarily delayed, while also enforcing the timely repair of crucial systems. This balance between operational flexibility and strict adherence to safety standards is one of the reasons why aviation continues to uphold its reputation for safety.

Ultimately, the MEL highlights the industry’s commitment to risk management, ensuring that every flight, regardless of minor technical issues, can be conducted safely, efficiently, and with the highest level of responsibility toward passengers and crew.